- Overview

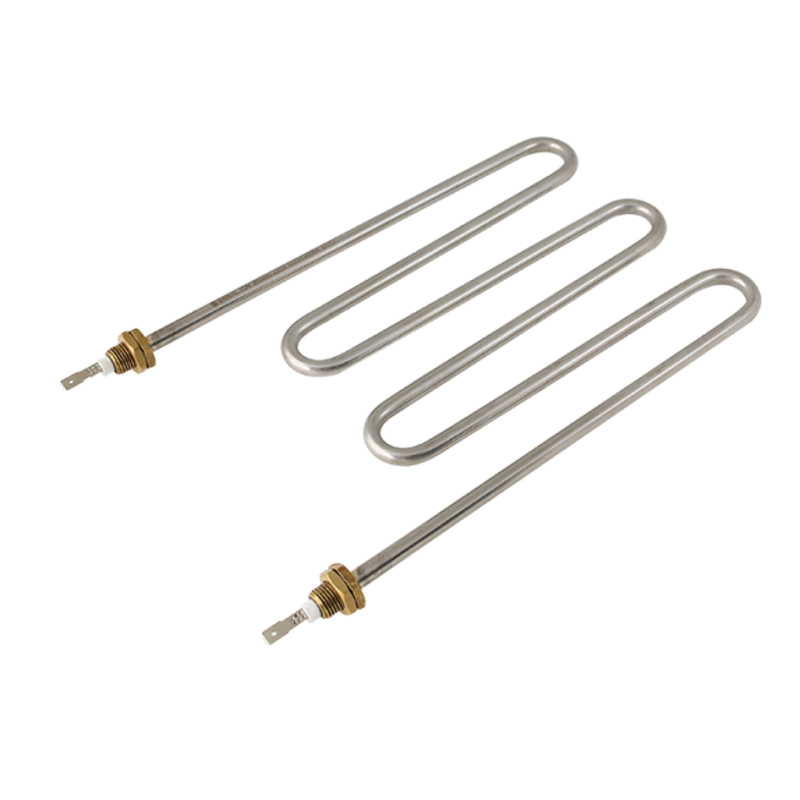

- Related Products

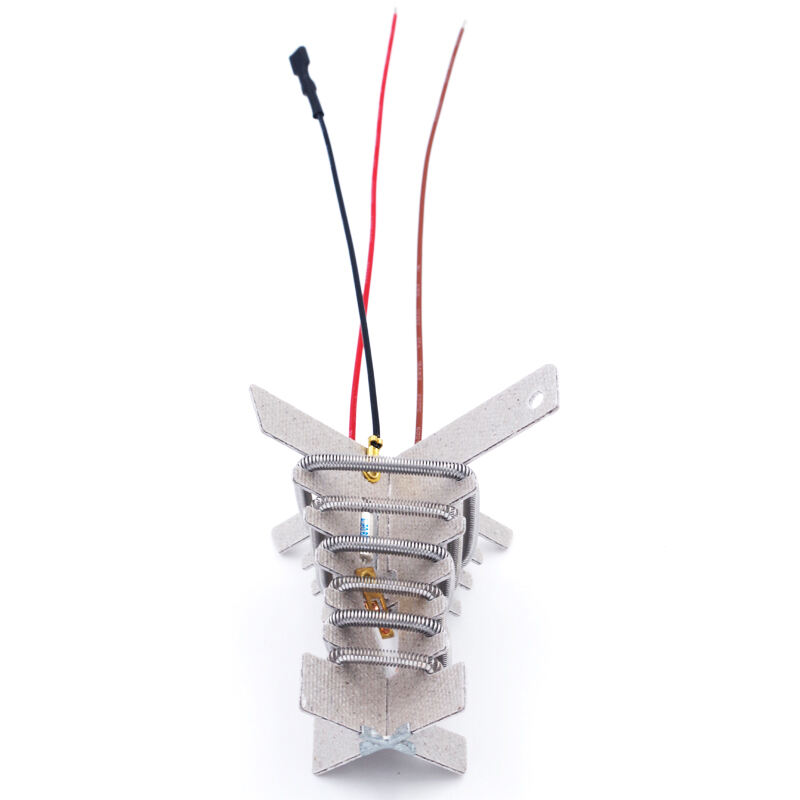

Ceramic band heaters are medium-to-high temperature heaters that have 600℃as a maximum working temperature. They provide long life and use less wattage (because of insulation) in plastics extrusion and injection molding applications.

Ceramic band heaters are available with different terminal styles, are fully flexible, and can accommodate holes and cut-outs. Yuheng Factory engineering is available to assist with the design and development of special heaters for particular requirements.

| Product name | Ceramic Band Heaters |

| Insulation Mateial | Ceramic Fiber Insulation |

| Wavelength range | 2-10 Microns |

| Max Wattage Density | 6 W/cm² |

| Wattage tolerance | +5% -10% |

| Operating Temperature | 300°C to 700°C (572°F – 1292°F) |

| Mini diameter | 60mm |

| Mini height: | 25.4mm |

| Standard Thickness | 12 mm |

| Standard gap | 9 mm |

| Operating Life-Up | 20000 hours |

Plastic processing requires high operating temperatures and fast production rates. The Ceramic Band Heaters are designed to meet these demands. These heater are, in effect, high temperature electric furnaces capable of very efficient heat transfer by radiation, conduction and convection. Built-in insulation minimizes unwanted temperature changes along the barrel.

Other types of band heaters are primarily conductive, requiring an intimate fit with components being heated. Grooves or other surface irregularities form voids under the bands, resulting in hot spots and premature heater failure. Ceramic bands are recommended here because efficient heat transfer is not affected by irregular surfaces or loose fit. At higher watt densities they can be used in wider increments than other heaters. This means you can reduce the number of bands used and simplify wiring.